Rom Bin

Location

Emerald, QLD

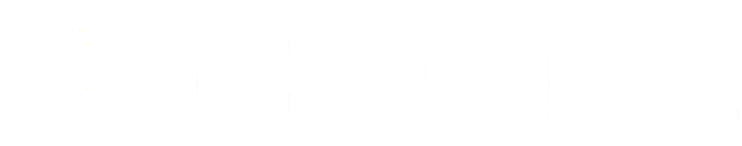

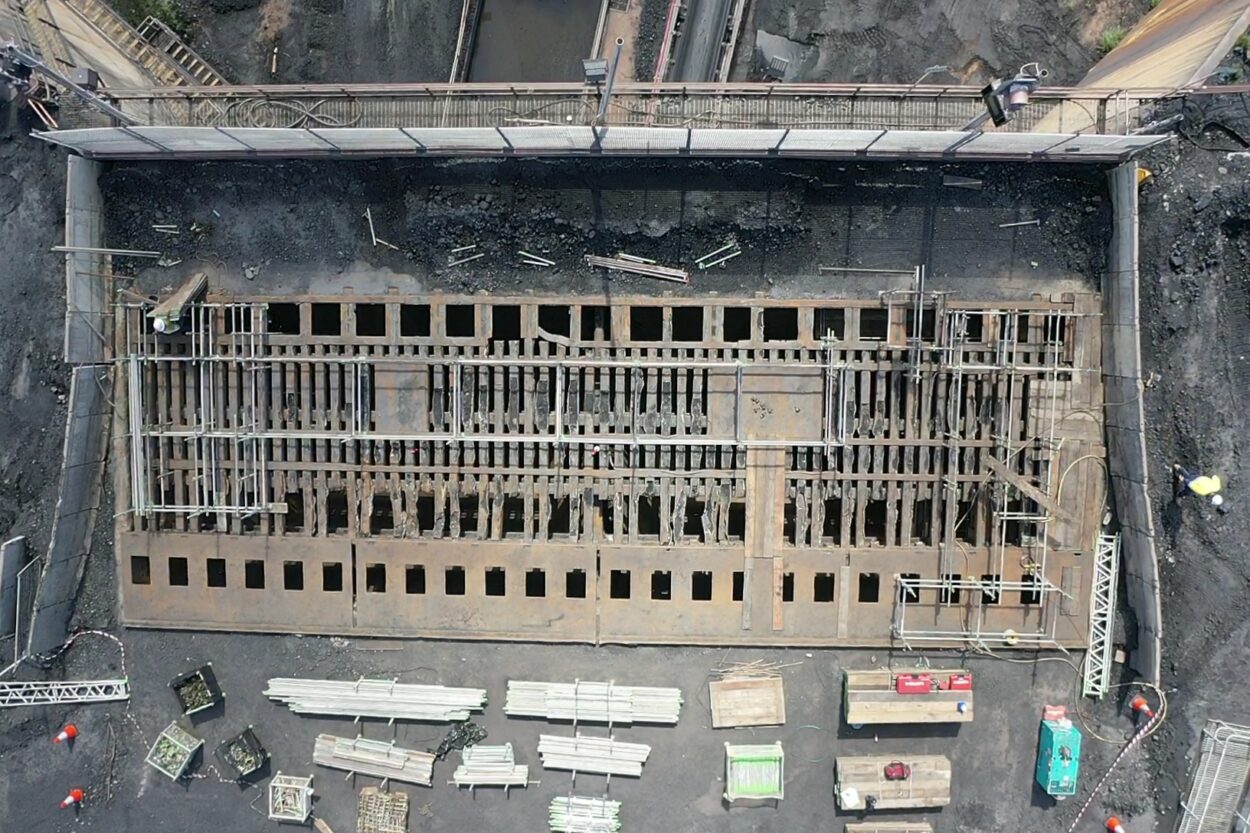

The ROM Bin structure at central Queensland, required a modification to continue operating under a new loading methodology. The new method required loading the ROM Bin in two ways, as follows:

- By side tipping into the ROM Bin, when a road train drives over the grizzly structure

- By front tipping with a CAT 992 Loader and a Liebherr T282B GB mining truck

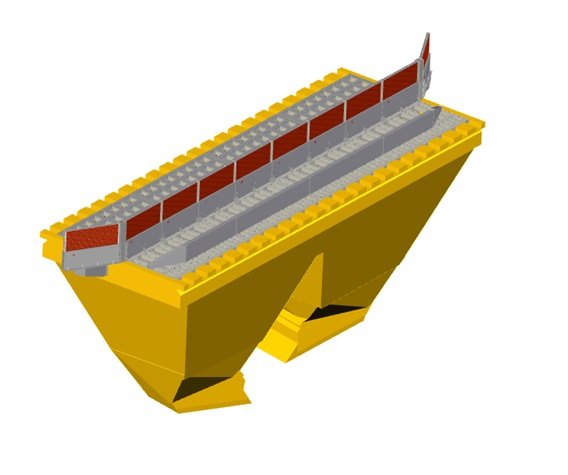

Mincka provided an in-depth assessment of the condition of the concrete hopper structure, along with the design of a new grizzly structure, which is modular in nature, and for which constituent parts can be replaced when required.

The Challenges

The mechanical and geometrical properties of the bin were unknown. The bin was constructed more than 20 years ago, so accurate information was unavailable for our analysis. In addition, the client wanted a new easy-to-install and easy-to-repair grizzly beam system, so special considerations were required in the design stage to meet the stated requirements.

The Solution

Concrete Conditions

- Mincka conducted visual inspections to identify any obvious concrete defects such as cracks, honeycombed areas, and staining from corrosion/efflorescence. A comprehensive delamination survey was also carried out on concrete surfaces that were easily accessible, to identify internally cracked/drummy cover concrete, and any concrete at risk of spalling.

- The slab and walls were scanned using Proceq Live ground penetrating radar (GPR) equipment, to locate reinforcement bars and to determine concrete cover depth.

- A Proceq Silver Schmidt live rebound hammer was used to test the hardness of accessible concrete wall surfaces. Surface hardness can be used non-destructively to estimate in situ concrete strength.

- Mincka assessed the concrete carbonation, cement content and chloride ingress on the 12 core samples, taken from various locations across the structure.

- Chloride ion ingress was determined by testing the core samples, typically by taking 3-4 discrete depth slices, according to AS1012.20.

Geometry

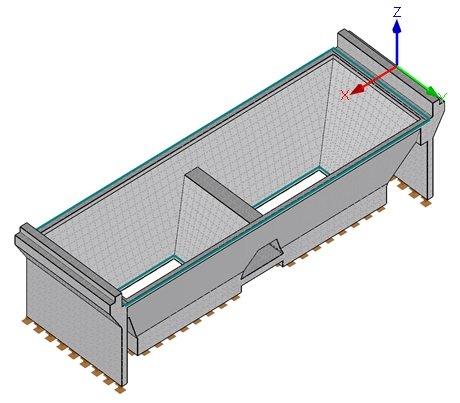

- Laser scan measurements were taken in the ROM Bin, in order to overcome the lack of information regarding its overall geometry. From the laser measurements a detailed CAD model was created, which allowed us to proceed to the design stages of the project.

Design

- Several meetings and field inspections were held. Having comprehensive knowledge with regards to risk assessment, governance, and mine operations allowed us to quickly establish the key features required for the design.

- After the initial design, Mincka conferred with the customer to get feedback and to ensure we were addressing their requirements and meeting their expectations.

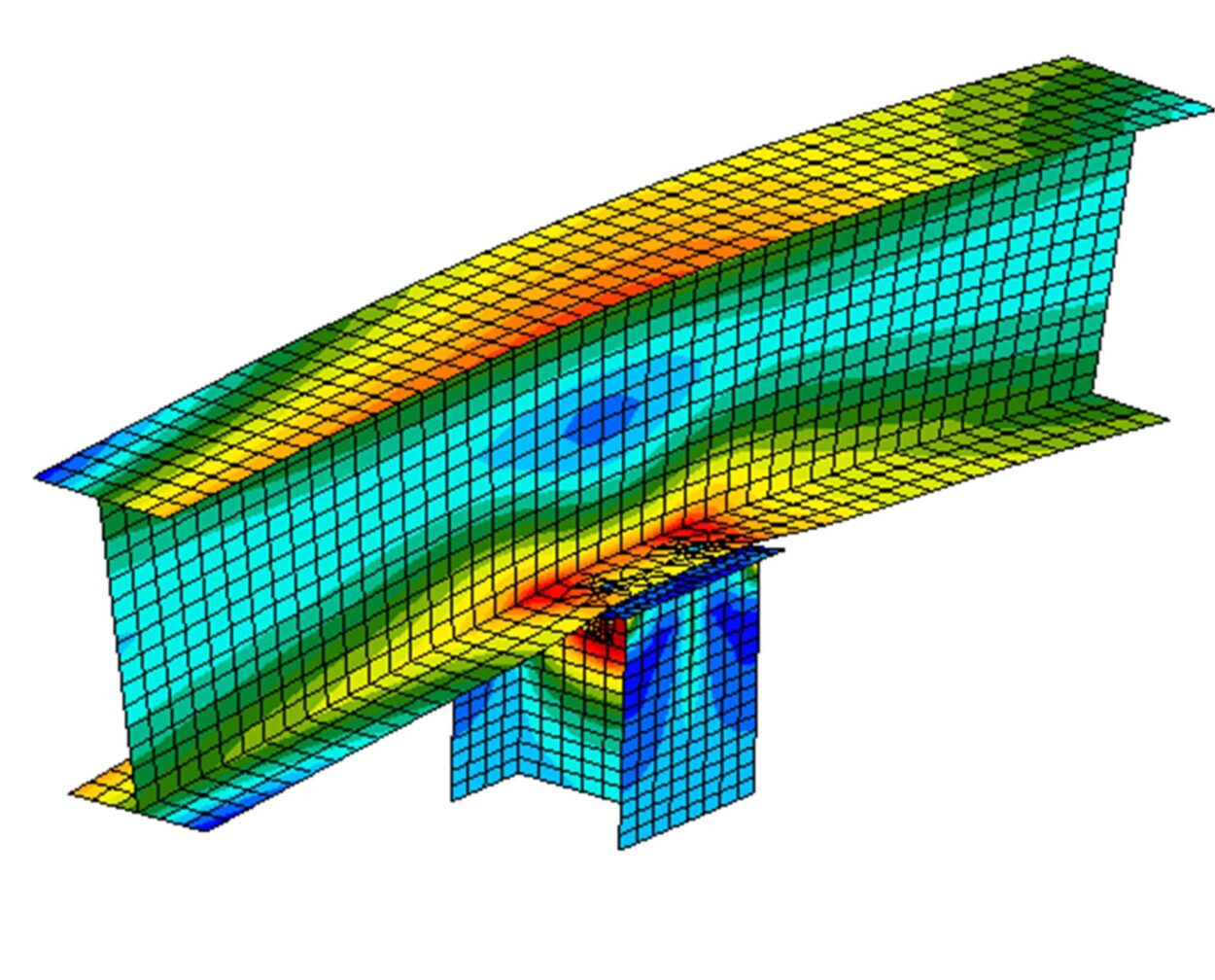

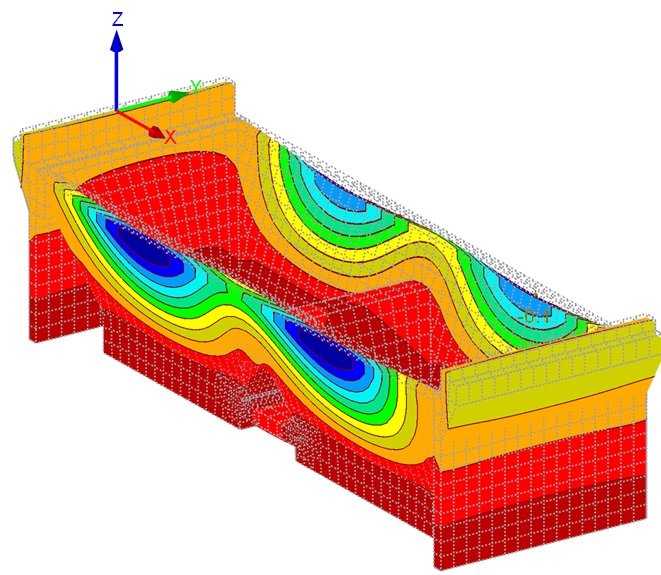

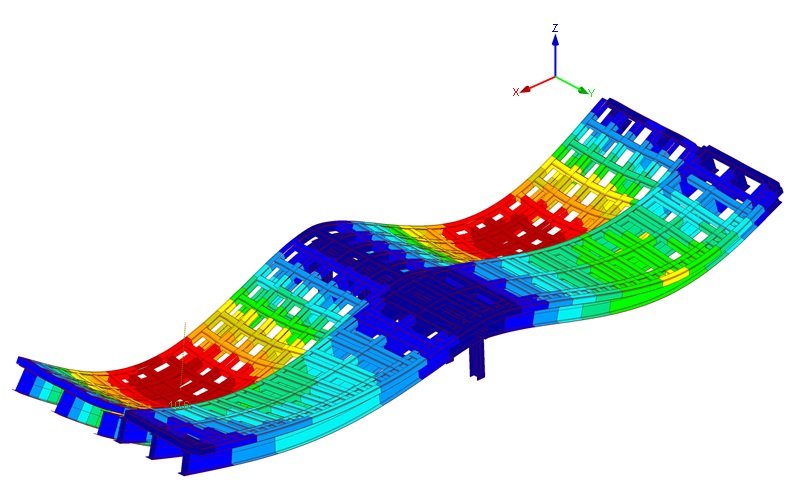

- The finite element models for both the concrete bin and grizzly beam arrangement were then completed.

- The structural design was carried out as per Australian standards, including AS1170, AS4100 and AS5100.

Design

- A complete Bill of Materials and structural drawings were delivered, providing a clear and detailed outline of the structural members required to construct the new grizzly system.

The Impact

- Our testing provided valuable insights regarding the condition of the ROM Bin concrete structure, which lead to better, more accurate decision-making for the stakeholders.

- The new loading methodologies increased both the production and the capacity at the mine.

- A new grizzly beam system will be installed into the ROM Bin, with an excellent return on investment.